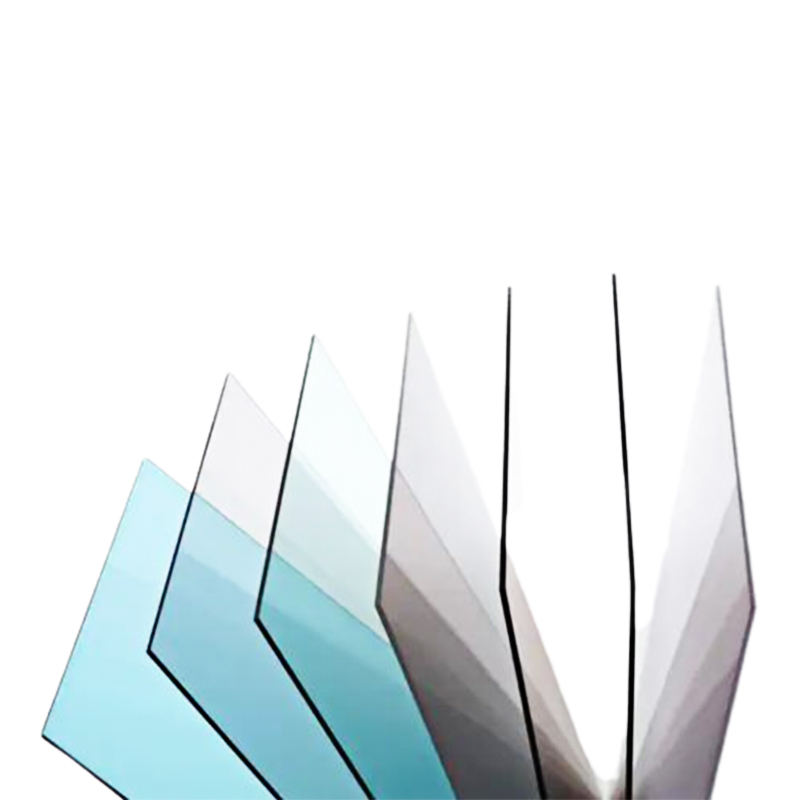

In the world of thermoplastic materials, PETG sheets have emerged as a go-to solution for a wide range of industrial, commercial, and DIY applications. Known for their excellent clarity, impact resistance, and ease of fabrication, Polyethylene Terephthalate Glycol-modified (PETG) sheets combine the best properties of acrylic and polycarbonate — offering strength without the brittleness and clarity without the complexity.

Available in various thicknesses and finishes — from clear to colored or textured — PETG sheets can be easily cut, drilled, thermoformed, vacuum-formed, and even 3D printed depending on the application.

Key Features of PETG Sheets

Excellent Clarity

Offers glass-like transparency, making it ideal for display cases, windows, and protective covers.

High Impact Resistance

More durable than acrylic and less expensive than polycarbonate, PETG resists cracking and shattering under stress.

Thermoformable

Can be heated and molded into complex shapes without losing structural integrity — perfect for custom parts and prototypes.

Chemical and Moisture Resistant

Resists water, oils, and many common chemicals, suitable for food-safe and medical applications.

Easy to Fabricate

Can be heat-bent, CNC-machined, laser-cut, and glued using common adhesives or solvents.

FDA-Compliant Grades Available

Certain PETG formulations meet food contact safety standards, allowing use in food packaging and dispensers.

Common Applications of PETG Sheets

Point-of-Purchase Displays : Retail stores use PETG to create eye-catching signs and product holders.

Protective Covers & Guards : Used in manufacturing facilities to shield machinery or workers from moving parts.

Medical Equipment : Clear shields, trays, and enclosures benefit from PETG’s sterilizability and clarity.

Food Packaging : Clear blister packs, trays, and containers made from FDA-approved PETG ensure product visibility and safety.

3D Printing Filaments : PETG is a popular choice among hobbyists and professionals due to its strength, minimal warping, and glossy finish.

Architectural Models & Prototypes : Designers appreciate its ease of shaping and transparency for mock-up development.

As industries continue to seek cost-effective, durable, and easy-to-process materials, PETG sheets are proving to be a versatile and reliable option. Whether you're creating packaging prototypes, building retail displays, or designing protective components, PETG offers a balance of clarity, toughness, and workability that few other plastics can match.

With its combination of performance and affordability, it's no wonder that PETG sheets are becoming a staple in workshops, factories, and innovation labs around the world.

English

English 中文简体

中文简体