In the world of plastic materials, where versatility, safety, and sustainability are becoming non-negotiable, PETG sheet stands out as a frontrunner. Known for its clarity, durability, and ease of fabrication, PETG (Polyethylene Terephthalate Glycol-modified) is quickly becoming the preferred material in a variety of industries—from packaging and medical applications to signage, displays, and interior design.

So, what makes PETG sheet such a compelling choice for manufacturers, designers, and product developers alike? Let’s explore the outstanding features and wide-ranging applications that make PETG an increasingly popular alternative to traditional materials like acrylic, polycarbonate, and PVC.

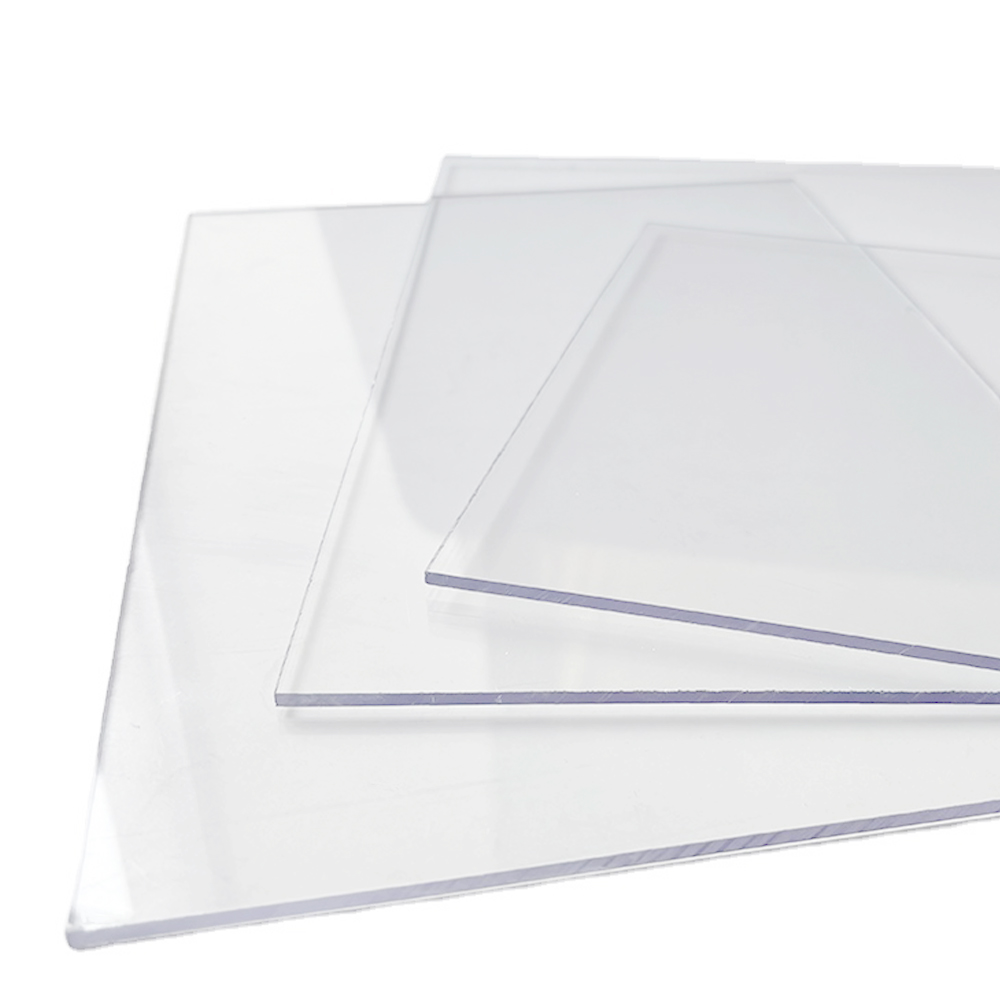

1. Superior Transparency and Aesthetic Appeal

PETG sheets offer excellent optical clarity, often achieving over 90% light transmission. Their crystal-clear appearance makes them ideal for applications where transparency is essential, Unlike acrylic, PETG does not yellow easily over time, maintaining its attractive look even in long-term use.

2. Impact Resistance Without the Brittleness

While acrylic sheets are known for their clarity, they can crack or shatter under pressure. PETG sheet offers a much higher impact resistance, similar to that of polycarbonate, but without its higher cost or processing difficulty.Its impact resistance also means fewer breakages during fabrication, shipping, or installation—saving money and reducing waste.

3. Easy to Fabricate and Thermoform

One of PETG’s greatest strengths lies in its excellent workability. It can be cut, drilled, bent, or printed on using conventional tools and processes. Even under heat, PETG maintains a stable form without bubbling or warping, making it a reliable choice for intricate or curved shapes.

4. Safe for Food and Medical Use

PETG is BPA-free and complies with FDA standards for food contact, making it a safe and popular option for:Its resistance to chemical and alcohol-based disinfectants makes it highly suitable for healthcare settings where cleanliness is critical.

5. Environmentally Friendly and Recyclable

In a world that is growing increasingly eco-conscious, PETG sheet provides an important advantage: 100% recyclability. It emits fewer volatile organic compounds (VOCs) during processing and leaves a smaller carbon footprint compared to alternatives like acrylic or PVC.

Many manufacturers are now opting for PETG not only for its performance but also for its environmental profile, especially in:

Sustainable packaging

Retail fixtures made from recycled materials

Green building interiors

Choosing PETG helps companies move toward circular economy models and greener production practices.

6. Cost-Effective Alternative to Polycarbonate

While polycarbonate is known for its toughness, PETG offers similar benefits at a more competitive price point and with fewer handling challenges. PETG doesn’t require pre-drying before forming, which saves time and energy in the production process.

Whether you're producing consumer goods, signage, or industrial components, PETG gives you great value for money without compromising on quality.

7. Wide Range of Thicknesses and Finishes

PETG sheet is available in multiple gauges, from ultra-thin films to thick panels, and can be finished in various styles,This flexibility makes it easy to tailor PETG sheets to the specific needs of different industries, from luxury cosmetics to rugged industrial tools.

As industries continue to evolve, the demand for materials that balance performance, safety, and environmental responsibility has never been higher. PETG sheet delivers on all fronts—offering the strength of polycarbonate, the clarity of acrylic, and the ease of use that manufacturers love.

Whether you are designing eye-catching retail displays, building protective medical equipment, or developing sustainable packaging solutions, PETG is the intelligent choice that meets modern expectations.

English

English 中文简体

中文简体