In today's industrial and commercial fields, the choice of materials has a decisive influence on the performance and market competitiveness of products. As a new type of thermoplastic material, PETG (polyethylene terephthalate copolymer) sheet is gradually becoming a leader in the plastic sheet market due to its excellent processing performance, mechanical strength and environmental protection characteristics. This article will discuss in detail the characteristics, application areas and development potential of PETG sheet in the future market.

PETG is a non-crystalline copolyester material made of terephthalic acid (PTA) and ethylene glycol (EG) as the main raw materials, and is made by adding a small amount of comonomer. Compared with traditional PET materials, PETG has higher transparency and better processing performance during the production process.

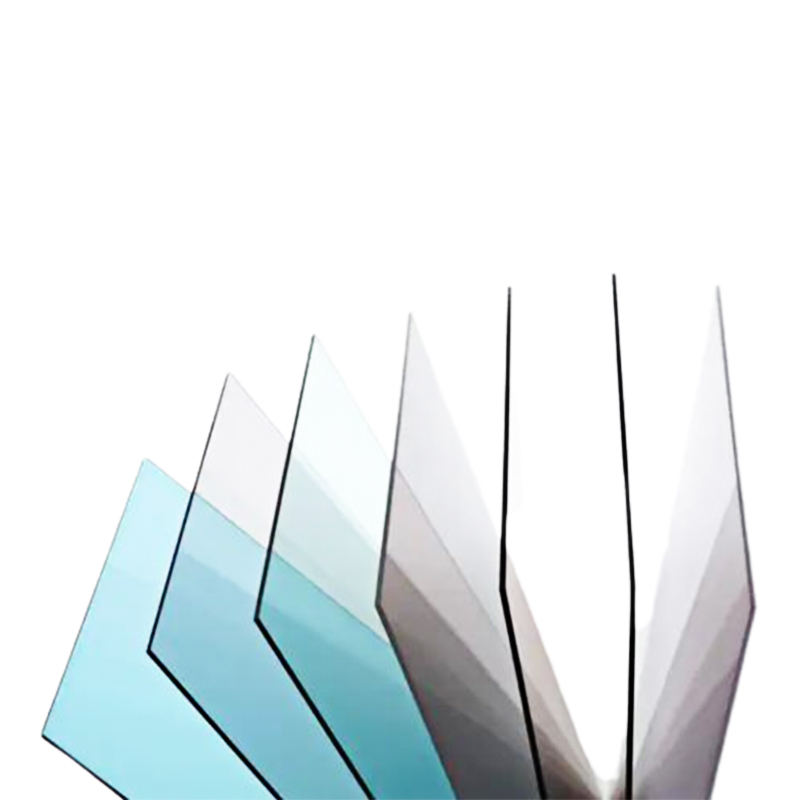

PETG sheet has high transparency close to glass and excellent gloss, which makes it very popular in applications that require visual effects, such as display cabinets, signboards, billboards, etc.

PETG sheet has better chemical resistance than most plastic materials and can resist the erosion of a variety of chemicals. At the same time, its excellent impact resistance allows PETG sheet to remain stable in high-intensity applications.

PETG sheet has excellent processing properties and can be processed by thermoforming, cutting, laser engraving and other methods. In addition, PETG sheet is not easy to deform or crack during high-temperature processing, making it suitable for the manufacture of products with complex shapes.

As an environmentally friendly material, PETG sheet not only reduces environmental pollution during production, but also has good recyclability. Compared with other plastics, PETG sheet does not release toxic gases when incinerated, making it a safe and environmentally friendly choice.

PETG sheet can maintain its mechanical properties and appearance quality under different climatic conditions, and will not age significantly due to long-term exposure to ultraviolet rays or moisture.

Due to its unique properties, PETG sheet is widely used in many industries and fields. The following are some of the main application scenarios:

PETG sheet is widely used in the manufacture of medical devices such as culture dishes, test tube racks, transparent packaging, etc. due to its excellent biocompatibility and easy disinfection characteristics. The application of PETG sheet in the medical field not only meets high standards of hygiene requirements, but also greatly reduces production costs.

In the food industry, PETG sheet is often used to make transparent food packaging boxes and beverage containers. Its high transparency, non-toxicity and good impact resistance make it an ideal choice for food packaging.

Due to its superior optical properties and processability, PETG sheets are often used for interior and exterior decoration of buildings, such as light boxes, display cabinets, door and window panels, etc. The diverse appearance design of PETG sheets provides more creative possibilities for architectural decoration.

In the advertising industry, PETG sheets are often used to make high-end display boards, billboards, POP display racks, etc. Its excellent transparency and durability make the advertising display effect more significant and enhance the visual impact of the brand.

PETG sheets are also commonly used in electronic product housings, panels and display screen protective films. Its high impact resistance and excellent optical properties provide better protection and aesthetic effects for electronic products.

In industrial manufacturing, PETG sheets can be used to make various industrial parts, such as protective covers, instrument panels, tool boxes, etc. Its high strength and easy processability make it popular in the industrial field.

With the enhancement of environmental awareness and the advancement of technology, PETG sheets have great development potential in the future market. The following are some important trends in its future development:

With the global emphasis on environmental protection and sustainable development, the environmental protection characteristics of PETG sheets will make it occupy a more important position in the future market. By improving the production process, reducing energy consumption and waste emissions, PETG sheets will occupy a larger share in the global plastics market.

With the continuous advancement of technology, PETG sheets will continue to expand their application areas, such as 3D printing, smart materials, aerospace and other emerging industries. Its excellent processability and performance will provide more innovative possibilities for these new fields.

With the increasing demand for high-performance plastic materials in various industries, the market demand for PETG sheets will continue to grow. Especially in the fields of medical, food packaging and architectural decoration, the application of PETG sheets will be further expanded.

With its excellent performance and diverse application areas, PETG sheets are becoming an indispensable material in modern industry and commerce. With the advancement of technology and changes in market demand, PETG sheets will play a more important role in the future, providing more environmentally friendly and efficient solutions for various industries. Through continuous innovation and development, PETG sheets are expected to occupy a larger share in the global plastics market and become an important member of future material selection.

English

English 中文简体

中文简体