PETG Sheet is a high-performance thermoplastic material that is widely used in packaging, medical devices, construction, and display industries due to its excellent processing performance, transparency, and durability. PETG Sheet is both functional and environmentally friendly. While meeting diverse needs, it conforms to the global trend of sustainable development. This article will explore in depth the characteristics, application scenarios, advantages, and future development prospects of PETG Sheet.

PETG Sheet is made of polyethylene terephthalate (PETG) and has a series of unique physical and chemical properties, making it an ideal choice for many industries. Its main features include:

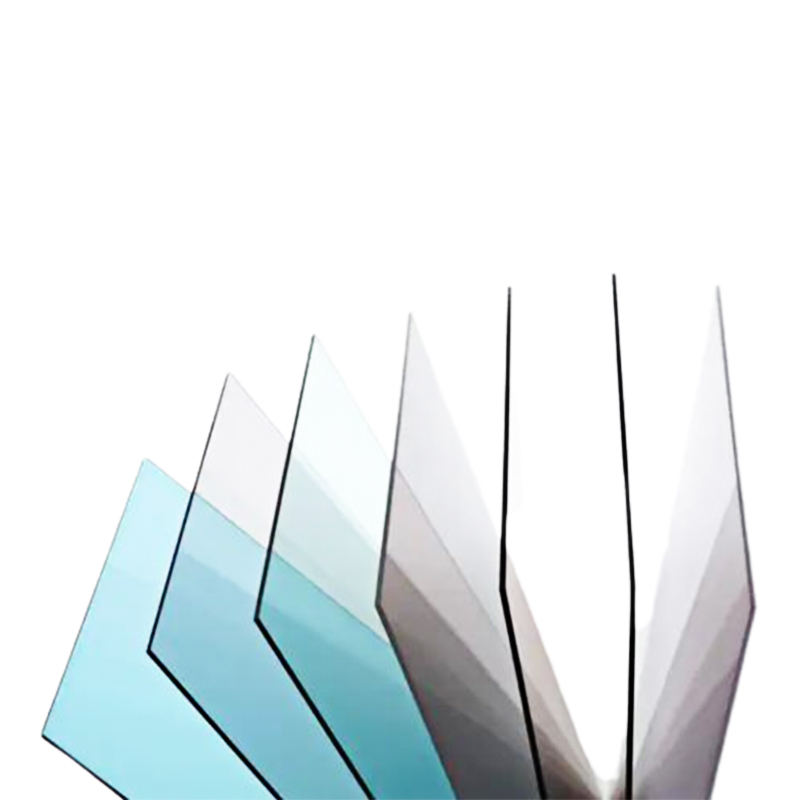

PETG Sheet has excellent optical transparency and a light transmittance of more than 90%. It is often used in occasions that require high-definition displays, such as billboards, display racks, and windows.

PETG Sheet can be easily processed by a variety of processing methods such as thermoforming, cutting, drilling, and printing, and no harmful substances or odors are generated during the processing. Its low-temperature processing characteristics make it suitable for a variety of complex design and molding needs.

PETG sheet has good toughness and impact resistance, can maintain stability in high-intensity use environments, is not easy to break or deform, and is suitable for products that are used for a long time.

PETG sheet has strong resistance to a variety of chemicals, including acids, alkalis and alcohol, which makes it perform well in applications that require protection and durability, such as medical device housings and chemical containers.

PETG sheet is a non-toxic and harmless material that meets food and medical grade standards. It is also 100% recyclable and is an environmentally friendly plastic material choice.

PETG sheet is widely used in food packaging, electronic product packaging, retail display racks and billboards due to its high transparency and excellent processing performance. Its superior optical properties make the packaging and display effects more outstanding.

Due to its good biocompatibility and chemical resistance, PETG sheet is widely used in the production of medical device housings, laboratory equipment and medical packaging, etc., to ensure that the product is safe and reliable during use.

PETG sheet is also widely used in the construction field, such as for the manufacture of transparent roofs, partition walls and security windows. Its durability and impact resistance make it an ideal choice for building materials.

In the industrial field, PETG sheets are used as protective covers, instrument panels, and mechanical parts to ensure the stable operation of equipment in harsh environments.

PETG sheets can easily undergo various processing operations, such as thermoforming, cutting, and printing, to meet different design requirements, and reduce production costs and time.

PETG sheets are not only non-toxic and harmless, but also completely recyclable, which meets the requirements of modern society for sustainable development and is of great significance in reducing environmental pollution.

The strength, toughness, and chemical resistance of PETG sheets enable them to maintain excellent performance in various harsh environments, extend the service life of the product, and reduce replacement and maintenance costs.

PETG sheets are becoming an important role in modern material science and technology with their excellent physical properties, environmental protection characteristics, and a wide range of application scenarios. With the continuous innovation of technology and the evolution of the market, PETG sheets will continue to play a key role in multiple fields and promote the sustainable development of modern industry and life.

English

English 中文简体

中文简体